Supreme Info About What Is Wire Hose

Ever Wondered About That Wire Hose Thingy? Let's Demystify It!

1. What in the World Is a Wire Hose?

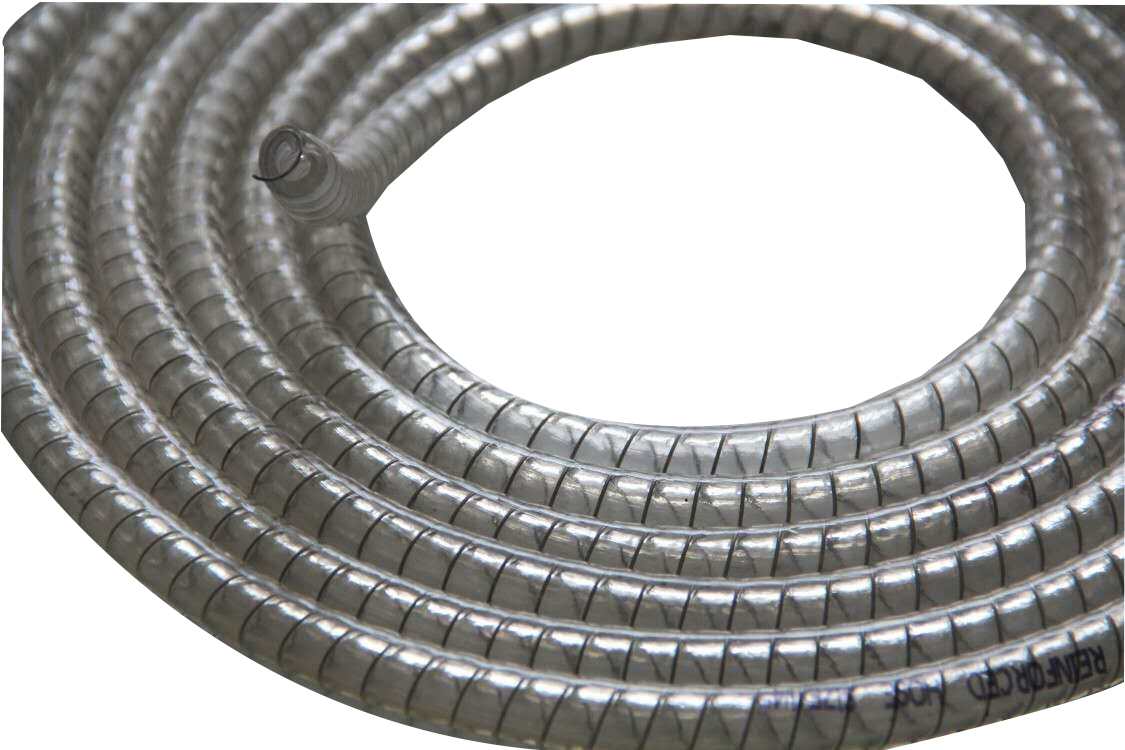

Okay, let's cut right to the chase. You might have heard the term "wire hose" thrown around, or maybe you spotted one lurking under the hood of your car and thought, "What's THAT doing there?" Simply put, a wire hose is a flexible hose reinforced with a wire helix, either embedded within the hose material or wrapped around the exterior. Think of it as a regular hose that hit the gym and got seriously buff! This reinforcement provides strength and prevents the hose from collapsing under suction or pressure.

Imagine trying to drink a milkshake with a flimsy straw. You suck, and the straw crumples. Annoying, right? A wire hose is the industrial-strength straw of the fluid transfer world. The wire prevents that crumpling, allowing for efficient and reliable movement of whatever's flowing through it.

The type of material used for the hose itself can vary widely — rubber, silicone, PVC, you name it. The choice depends entirely on what the hose needs to carry. Think about it: you wouldn't use a garden hose to transport gasoline, would you? (Please say no!). Similarly, the wire can be made from different metals, often steel or aluminum, chosen for their strength, corrosion resistance, and flexibility.

So, while the specific makeup can change, the core concept remains: a robust, reinforced hose built for the tough jobs. Its like the Swiss Army knife of fluid conveyance! It's designed to stand up to abuse and keep things flowing smoothly (literally!).

Flexible Reinforced Spiral Spring PVC Steel Wire Hose

Where Do You Find These Wire-Wrapped Wonders?

2. A World of Applications, From Cars to Vacuums!

Wire hoses are everywhere! Seriously, once you know what to look for, you'll start spotting them all over the place. They're incredibly versatile and pop up in a surprising number of applications.

In the automotive world, you'll find them used as radiator hoses, fuel lines, and vacuum hoses. Their ability to withstand high temperatures, pressure, and constant flexing makes them ideal for keeping your car running smoothly. That wriggling under-the-hood spaghetti? Some of that is definitely wire hose!

Then there's the industrial sector. Wire hoses are workhorses in factories, construction sites, and agricultural settings. They're used for everything from transferring chemicals and solvents to moving abrasive materials like sand and gravel. Without them, many industrial processes would grind to a halt.

Even your trusty vacuum cleaner relies on a wire hose! That flexible hose you use to suck up dust bunnies is often reinforced with wire to prevent it from collapsing and losing suction. So, next time you're vacuuming, take a moment to appreciate the unsung hero that's keeping your floors clean.

Picking the Right Wire Hose

3. Selecting a Wire Hose

Choosing the correct wire hose isn't just about grabbing the cheapest one you can find. It's about matching the hose to the job. Think of it like buying shoes — you wouldn't wear flip-flops to climb a mountain, right? Same principle applies here.

First, consider the material. What's going to be flowing through the hose? Chemicals, water, oil, abrasive materials? The hose material needs to be compatible with whatever it's carrying to prevent corrosion, degradation, or even complete failure. Check the manufacturer's specifications for chemical resistance.

Next up: pressure and temperature. How much pressure will the hose be subjected to? What's the operating temperature range? Make sure the hose is rated for the maximum pressure and temperature you expect to encounter. Going beyond those limits is a recipe for disaster (and potentially a messy one!).

Finally, think about the environment. Will the hose be exposed to sunlight, ozone, or other environmental factors that could cause it to break down over time? UV-resistant hoses are available for outdoor applications. Also, consider the flexibility needed. A tight bend radius may require a more flexible hose construction.

When Things Go Wrong

4. Sniffing Out Problems

Even the toughest wire hose isn't invincible. Over time, wear and tear can take their toll, leading to leaks, cracks, or even complete failure. Knowing the signs of trouble can help you prevent a major headache down the road.

The most obvious sign is a leak. If you spot fluid dripping from the hose, investigate immediately. A small leak can quickly turn into a big one, and nobody wants a fountain of [insert fluid here] erupting from their equipment. Look for cracks, blisters, or any other signs of damage to the hose material.

Another common problem is kinking. If the hose is repeatedly bent beyond its recommended bend radius, it can develop kinks that restrict flow. A kinked hose is like a clogged artery — it can severely impact performance. Try to reposition the hose to eliminate the kink, or replace it if the damage is too severe.

Also, pay attention to the overall condition of the wire reinforcement. If the wire is corroded, broken, or pulled away from the hose material, it's a sign that the hose is nearing the end of its life. Replacing a worn-out hose is a lot cheaper (and less messy) than dealing with a catastrophic failure.

Wire Hose

5. More Than Just a Hose

So, there you have it! A deep dive into the wonderful world of wire hoses. They might seem like a small, insignificant component, but they play a crucial role in countless applications. From keeping your car running smoothly to powering industrial processes, these reinforced hoses are the unsung heroes of many industries.

Next time you see a wire hose, take a moment to appreciate the engineering that goes into making it so durable and reliable. It's a testament to the power of simple, yet effective design. They quietly perform their duty, often unnoticed, but without them, a lot of things wouldn't get done!

Understanding the different types of wire hoses, their applications, and how to troubleshoot potential problems can save you time, money, and a whole lot of frustration. So, the next time you're faced with a hose-related challenge, remember what you've learned here, and you'll be well-equipped to tackle it head-on.

Hopefully, this has shed some light on the mysterious "wire hose." Now you can impress your friends with your newfound knowledge. Just try not to bore them with too much detail! After all, even the most interesting topic can become tedious if overexplained. Just casually drop it into conversation like, "Oh, that? That's a wire hose. They're everywhere, you know."

Frequently Asked Questions (FAQs)

6. Your Wire Hose Questions Answered!

Q: What's the difference between a wire hose and a regular hose?A: The key difference is the wire reinforcement. Wire hoses have a wire helix (either inside or outside) that provides added strength and prevents collapsing, especially under suction. Regular hoses don't have this reinforcement.

Q: Can I use any wire hose for any fluid?A: Absolutely not! The hose material must be compatible with the fluid being transferred. Using the wrong hose can lead to degradation, leaks, and even dangerous situations. Always check the manufacturer's specifications.

Q: How do I clean a wire hose?A: The cleaning method depends on what the hose has been carrying. Generally, flushing with water or a suitable cleaning solvent is recommended. Avoid using harsh chemicals that could damage the hose material. Always consult the manufacturer's instructions.

Q: What is the 'wire hose' keyword part of speech?A: In the term "wire hose," "wire" functions as an adjective describing the type of hose. "Hose" is the noun. The entire term "wire hose" then functions as a noun phrase.