Matchless Info About Is A VFD An Inverter

Unraveling the Mystery

1. Decoding the Acronyms

Okay, let's be real. Technical jargon can feel like navigating a jungle. So, before we dive headfirst into the question of whether a VFD is an inverter, let's break down what these acronyms actually mean. A VFD stands for Variable Frequency Drive. An inverter, well, it's an inverter! Just kidding (sort of). Inverters are electrical devices that convert direct current (DC) to alternating current (AC). Think of it like this: DC is a calm, steady stream, while AC is a more fluctuating, energetic wave.

Now, what does a Variable Frequency Drive do? Simply put, it controls the speed of an AC motor by varying the frequency of the power supplied to it. Imagine a dimmer switch for a light, but instead of dimming light, it's controlling the speed of a motor. This is incredibly useful in countless applications, from industrial pumps and fans to elevators and even electric vehicles. It's all about having precise control and optimizing energy usage, and extending the life of your machinery by not hammering them into max speed all the time! Because who likes being hammered?

So, we've got our players: the VFD, the inverter, AC, and DC. All are related, but how do they fit together? That's the puzzle we're here to solve. And trust me, even if you're not an electrical engineer (and I suspect many of us aren't), you can absolutely understand the core concept. It's actually less intimidating than remembering all the ingredients in your grandma's secret sauce. (Though both are equally valuable knowledge!)

Think of a VFD as a complete system, a package deal, a well-orchestrated team, if you will. It's got several components working together to make the magic happen. It's not just one thing; it's a whole squad! Keep that image in your mind as we move forward, and things will start to click into place. I promise, by the end of this, you'll be able to confidently explain this to your friends at your next barbecue (or maybe just nod knowingly when someone else mentions it).

Why VFDs Are Known As Inverters Understanding The TerminologyCM

The Inverter

2. The Heart of the Matter

Here's the kicker: the inverter is actually a part of the VFD. It's one of the crucial components that allows the VFD to do its job. Remember how we said VFDs control motor speed by changing the frequency of the power supplied? Well, the inverter is the section of the VFD that is responsible for actually generating that variable frequency AC power. It's like the engine in a car — essential for making the whole thing go. Without the inverter, the VFD would be just a fancy box of wires. No power, no magic, no motor control.

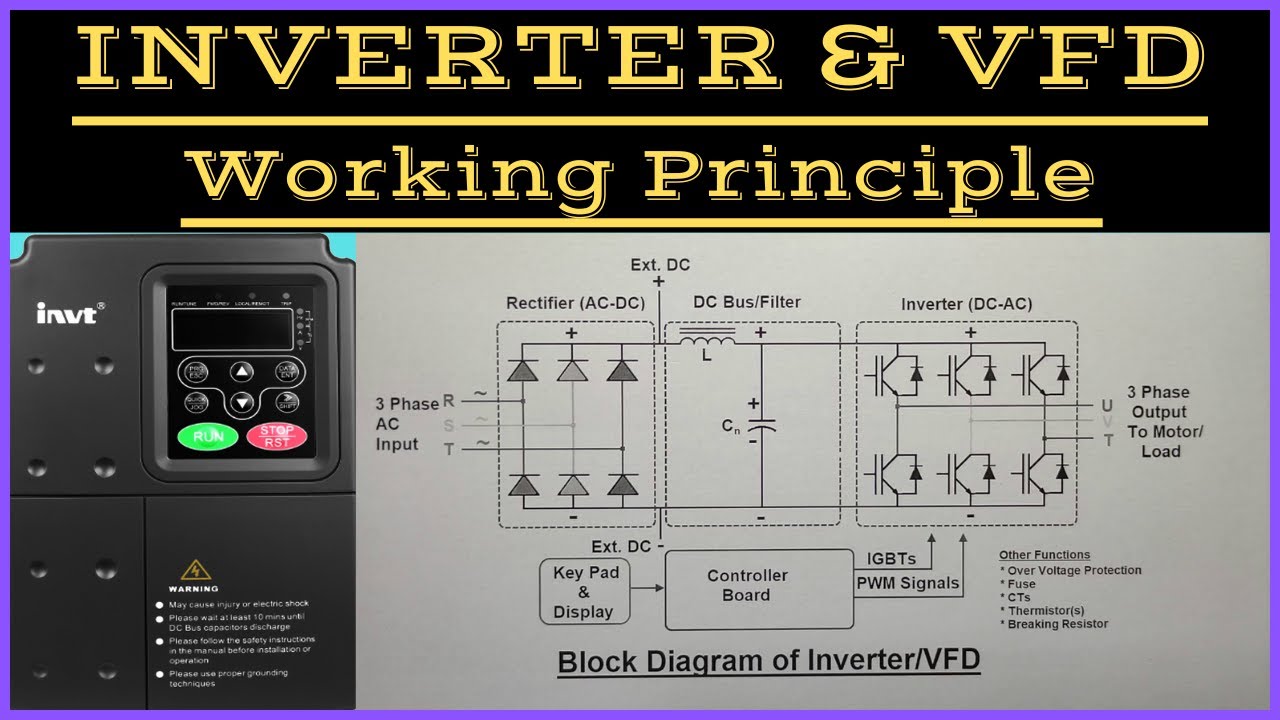

Inside a typical VFD, you'll usually find a rectifier, which converts the incoming AC power from the mains into DC power. Then, that DC power goes to the inverter. The inverter then uses a sophisticated switching system (usually involving transistors) to chop up the DC power and recreate it as AC power at the desired frequency. Think of it like taking a smooth block of clay (DC) and sculpting it into a wave (AC) using tiny, precise cuts. By changing the speed and pattern of those cuts, you can control the frequency of the AC wave.

So, to recap, the AC goes to DC (rectifier), and then the DC goes back to a different kind of AC (inverter). This double conversion is what allows the VFD to precisely manipulate the motor's speed. It might seem inefficient to convert power back and forth, but the control it gives you over the motor is well worth it. And modern VFDs are designed to be quite efficient, minimizing energy losses during the conversion process.

In essence, the inverter is the muscle within the VFD, flexing its electronic circuits to control the motor. It's not the whole package, but it's an absolutely vital part of the overall system. So, while you can't say that a VFD is an inverter, you definitely can't have a VFD without one! It's like saying you can't have a cake without flour — technically true, but it's only one ingredient.

2.2kW VFD Drive Inverter, 220VAC SinglePhase Variable Frequency

Beyond the Basics

3. The Added Value

Now that we've established that the inverter is a key ingredient in the VFD recipe, let's talk about what else goes into the mix. A VFD isn't just an inverter; it's a sophisticated control system that includes a lot of other crucial elements. These elements work together to protect the motor, optimize its performance, and provide valuable data about its operation. These components include rectifiers, DC link capacitors, control circuitry, and protective features. It's like comparing a basic cell phone to a smartphone; they both make calls, but a smartphone does so much more.

One of the most important functions of a VFD is protection. VFDs are designed to safeguard the motor from overcurrent, overvoltage, undervoltage, and other potentially damaging conditions. They do this by constantly monitoring the motor's performance and shutting down the system if anything goes wrong. This protection can significantly extend the lifespan of the motor and prevent costly repairs. A VFD can be like a bodyguard for your motor! This is important when you are dealing with expensive machinery or processes that are critical to your operation.

Furthermore, VFDs offer a range of control features that go far beyond simply adjusting the motor's speed. They can be programmed to follow complex speed profiles, automatically adjust speed based on load, and even communicate with other control systems. This level of control allows for highly optimized performance and significant energy savings. Imagine being able to fine-tune your motor's operation to perfectly match the needs of the application. That's the power of a VFD.

Finally, modern VFDs often provide valuable data about the motor's performance. They can track parameters such as speed, current, voltage, and power consumption, and even transmit this data to a central monitoring system. This information can be used to identify potential problems early on, optimize energy usage, and improve overall system efficiency. A VFD is not just about controlling speed; it's about providing valuable insights into your motor's operation.

4kw Vfd Variable Frequency Drive Inverter Avr Technique Perfect Motor

Applications

4. Real-World Examples

So, we know what VFDs are, we know they contain inverters, and we know they do more than just invert. But where do you actually see them in action? The answer is: everywhere! From the mundane to the complex, VFDs are quietly working behind the scenes to make our lives easier and more efficient.

Think about the HVAC system in your office building. VFDs are often used to control the speed of the fans and pumps that circulate air and water. By adjusting the speed of these motors to match the actual demand, the system can save significant amounts of energy. Or consider the elevators in that same building. VFDs provide smooth and precise control over the motor, making for a comfortable and safe ride. They also help to reduce wear and tear on the elevator system, extending its lifespan.

In industrial settings, VFDs are used in a vast array of applications. They control the speed of pumps in water treatment plants, the speed of conveyor belts in manufacturing facilities, and the speed of mixers in chemical processing plants. They are also used in mining operations, oil and gas refineries, and power generation facilities. In each of these applications, VFDs provide precise control, energy savings, and improved system reliability.

Even in our homes, VFDs are becoming increasingly common. They are used in some washing machines and dishwashers to provide more efficient and quieter operation. They are also used in some air conditioners and heat pumps to provide more precise temperature control and reduce energy consumption. So, the next time you're using one of these appliances, take a moment to appreciate the VFD that's working behind the scenes.

Inverter VFD Variable Frequency Drive Working Principle

In Conclusion (Sort Of)

5. Bringing It All Together

Let's revisit the original question: Is a VFD an inverter? The answer, as we've explored, is a resounding no, but it contains one. An inverter is a critical component of a VFD, responsible for converting DC power to variable-frequency AC power. But a VFD is much more than just an inverter. It's a sophisticated control system that includes a rectifier, DC link capacitors, control circuitry, and protective features. These components work together to protect the motor, optimize its performance, and provide valuable data about its operation. Think of it as an orchestra, where the inverter is a key instrument, but it takes the entire orchestra to create a symphony.

Understanding this relationship is important because it helps us to appreciate the full capabilities of VFDs. They are not simply devices for changing motor speed; they are powerful tools for improving efficiency, reducing energy consumption, and extending the lifespan of motors. By understanding how they work, we can better leverage their capabilities and unlock their full potential.

So, the next time someone asks you if a VFD is an inverter, you can confidently explain the difference. You can tell them that the inverter is a vital part of the VFD, but that the VFD is a complete system with many other important components. You can even impress them with your knowledge of rectifiers, DC link capacitors, and control circuitry. And who knows, you might even inspire them to learn more about the fascinating world of electrical engineering.

Ultimately, the key takeaway is that VFDs are complex and versatile devices that offer a wide range of benefits. By understanding their inner workings, we can better appreciate their value and use them to create more efficient, reliable, and sustainable systems. And that's something we can all get behind!

Frequently Asked Questions (FAQs)

6. Your Burning Questions Answered

Still got questions? Of course, you do! Here are some common questions about VFDs and inverters, answered in plain English:

Q: Can I use an inverter by itself to control a motor's speed?A: Technically, yes, you could use a basic inverter. However, it won't have the protection features, advanced control options, and monitoring capabilities of a VFD. It's like trying to drive a race car with just an engine and no brakes — possible, but not recommended!

Q: Are all VFDs the same?A: Nope! VFDs come in different sizes, voltage ratings, and with varying features. The right VFD for you will depend on the specific application and the motor you're trying to control. Selecting the proper VFD for the application is crucial.

Q: Are VFDs expensive?A: The initial cost of a VFD can be significant, but the energy savings and reduced maintenance costs can often offset that cost over time. Think of it as an investment that pays off in the long run. Plus, a lot of places have rebates to help encourage you to invest in energy efficiency!

Q: Can VFDs be used with any type of motor?A: VFDs are designed for use with three-phase AC induction motors, which are the most common type of motor used in industrial applications. While it's possible to use them with other motor types, it may require special considerations and adjustments.