Fabulous Info About What Is BOM In Procurement

Unlocking the Mystery

1. Decoding the BOM

Ever feel like procurement is a giant puzzle? You're not alone! There are acronyms galore, processes that can seem unnecessarily complex, and enough jargon to make your head spin. Today, we're tackling one of those acronyms: BOM. But don't worry, this isn't about dropping bombs; it's about understanding a Bill of Materials, a critical element in successful procurement.

A BOM, or Bill of Materials, is essentially a comprehensive list of all the raw materials, components, assemblies, and even the quantities of each, required to manufacture a product. Think of it as a recipe for your product. Without it, you're basically trying to bake a cake without knowing what ingredients you need a recipe for disaster, quite literally! It might sound simple, but a well-structured BOM is the backbone of efficient procurement and manufacturing. Imagine trying to build a car without knowing you needed tires that's the kind of chaos a missing or inaccurate BOM can cause.

In the context of procurement, the BOM is far more than just a list. It's a crucial document that guides the entire sourcing and purchasing process. Procurement teams rely on the BOM to identify suppliers, request quotes, negotiate prices, and ultimately, ensure that the right materials are available at the right time, in the right quantities, and at the right price. This ensures your production lines run smoothly, avoiding costly delays and keeping customers happy. It's like having a detailed shopping list before hitting the grocery store, except the stakes are much, much higher!

So, why is understanding the BOM so important for procurement professionals? Because accuracy is key! An inaccurate BOM can lead to incorrect orders, material shortages, production delays, and ultimately, increased costs. Think about it: ordering the wrong quantity of a critical component can halt your entire production line, impacting delivery schedules and potentially damaging your reputation. A good BOM helps you avoid these pitfalls, ensuring your procurement process is efficient, cost-effective, and, dare I say, stress-free. It's the difference between a well-oiled machine and a rusty contraption constantly breaking down. And nobody wants to work with the latter!

Why BOM Matters

2. BOM's Role in Strategic Sourcing

Okay, so we know what a BOM is. But why should procurement professionals truly care? It's not just about having a list; it's about leveraging that list to optimize the entire procurement process. The BOM is your secret weapon in the fight against waste, inefficiency, and cost overruns. It's the key to unlocking strategic sourcing and building stronger supplier relationships.

Firstly, the BOM enables better demand forecasting. By analyzing the components required for each product, procurement teams can anticipate future material needs and plan their purchasing strategies accordingly. This proactive approach helps avoid last-minute rushes, allowing for better price negotiation and more favorable contract terms. It's like knowing what everyone will order at a restaurant before they even look at the menu a serious advantage!

Secondly, a well-structured BOM facilitates supplier identification and evaluation. With a detailed list of required materials, procurement teams can easily identify potential suppliers and compare their capabilities, pricing, and lead times. This ensures that you're always working with the best suppliers for your specific needs. You're not just picking the first supplier that pops up; you're making informed decisions based on data and analysis.

Thirdly, the BOM promotes standardization and simplification. By standardizing components and materials across different products, companies can reduce the number of unique items they need to manage, simplify their procurement processes, and leverage economies of scale. This not only reduces costs but also improves efficiency and reduces the risk of errors. This is akin to using the same basic building blocks to create different structures - more efficient and less confusing.

Finally, having a clear BOM makes risk management more manageable. You can use the BOM to identify single-source suppliers and plan for alternatives. What if your sole supplier for widget x goes belly up? The BOM helps you anticipate these problems and prepare solutions before they disrupt your business.

Types of BOM

3. Different BOM Structures for Different Needs

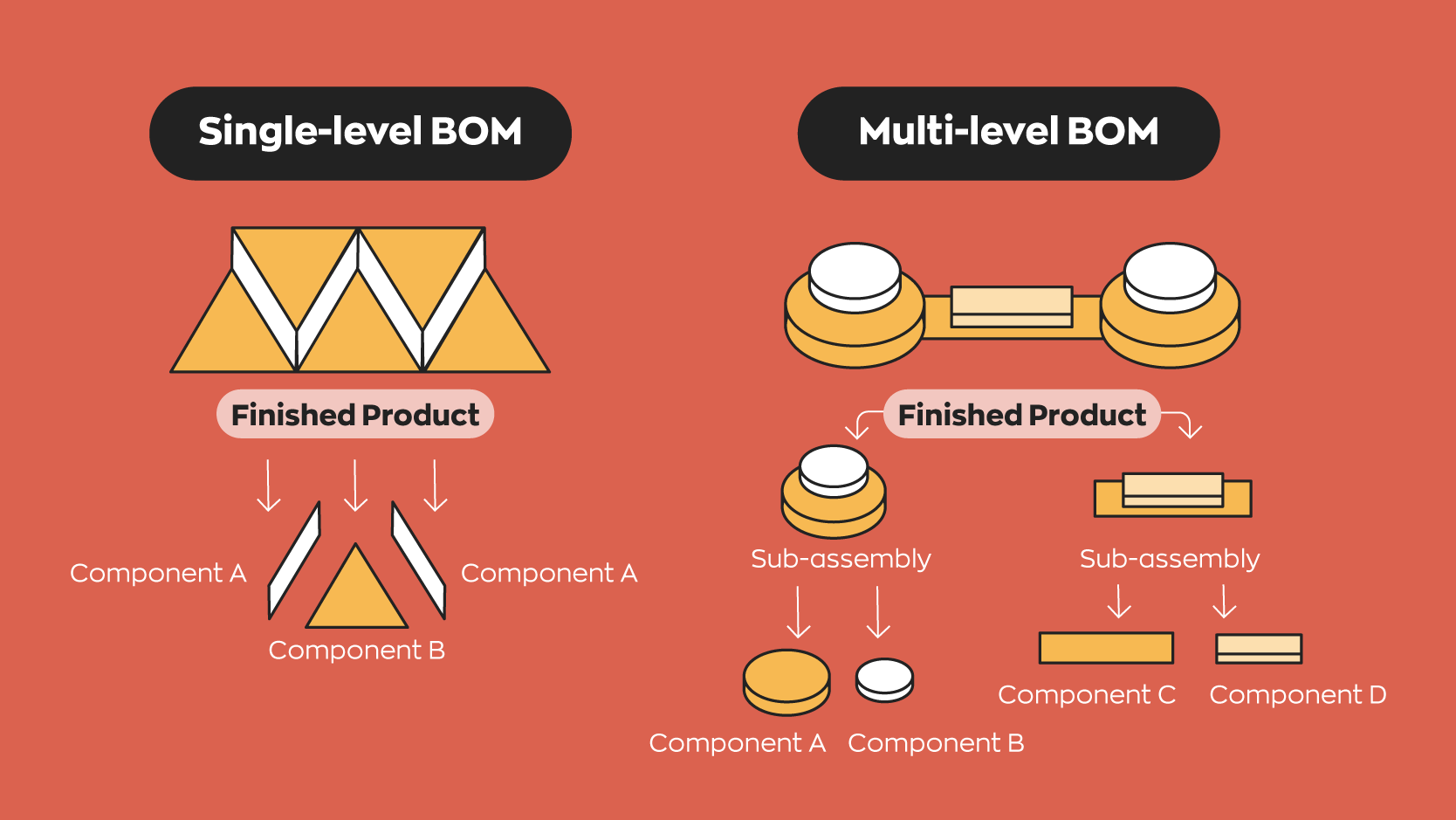

Just like there are different types of sandwiches, there are also different types of Bills of Materials. And choosing the right one for your specific needs is crucial for maximizing its effectiveness. Understanding the various BOM structures ensures that your procurement team is working with the most relevant and accurate information.

One common type is the Engineering BOM (EBOM). This BOM represents the product as designed by the engineering department. It focuses on the technical aspects of the product and may include information that's not directly relevant to procurement, such as CAD drawings and design specifications. Think of it as the architect's blueprint.

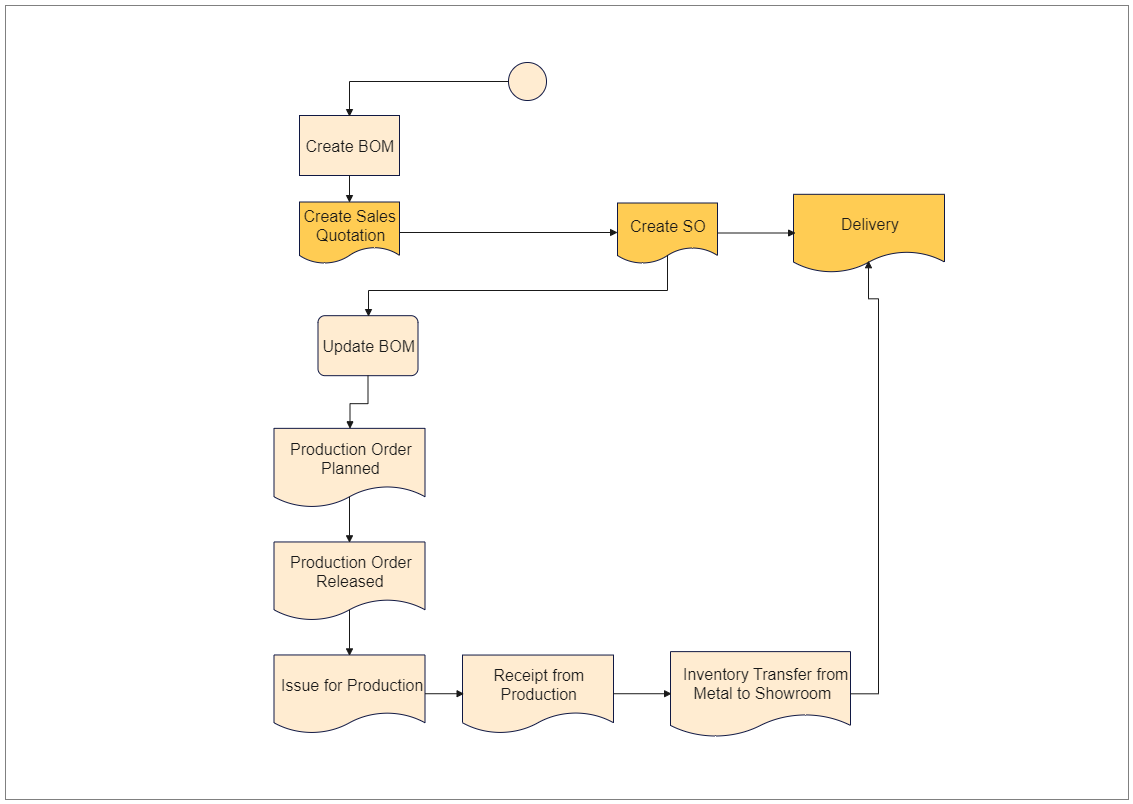

Then there's the Manufacturing BOM (MBOM). This BOM represents the product as it's actually manufactured. It takes into account the specific manufacturing processes, tools, and equipment used, as well as any changes or modifications made during production. The MBOM is what procurement uses primarily to source goods.

Another type is the Sales BOM (SBOM) or Configurable BOM. It defines a product at the sales stage. This is most commonly used when a customer can define the product or when a product is assembled on demand at the time of purchase.

There are also some other less common types like Service BOM and Production BOM. Ultimately, you must know each type of BOM and how they relate to each other. You could have your engineering team working off the wrong BOM if they do not know the different types.

BOM and Technology

4. Leveraging Technology for BOM Management

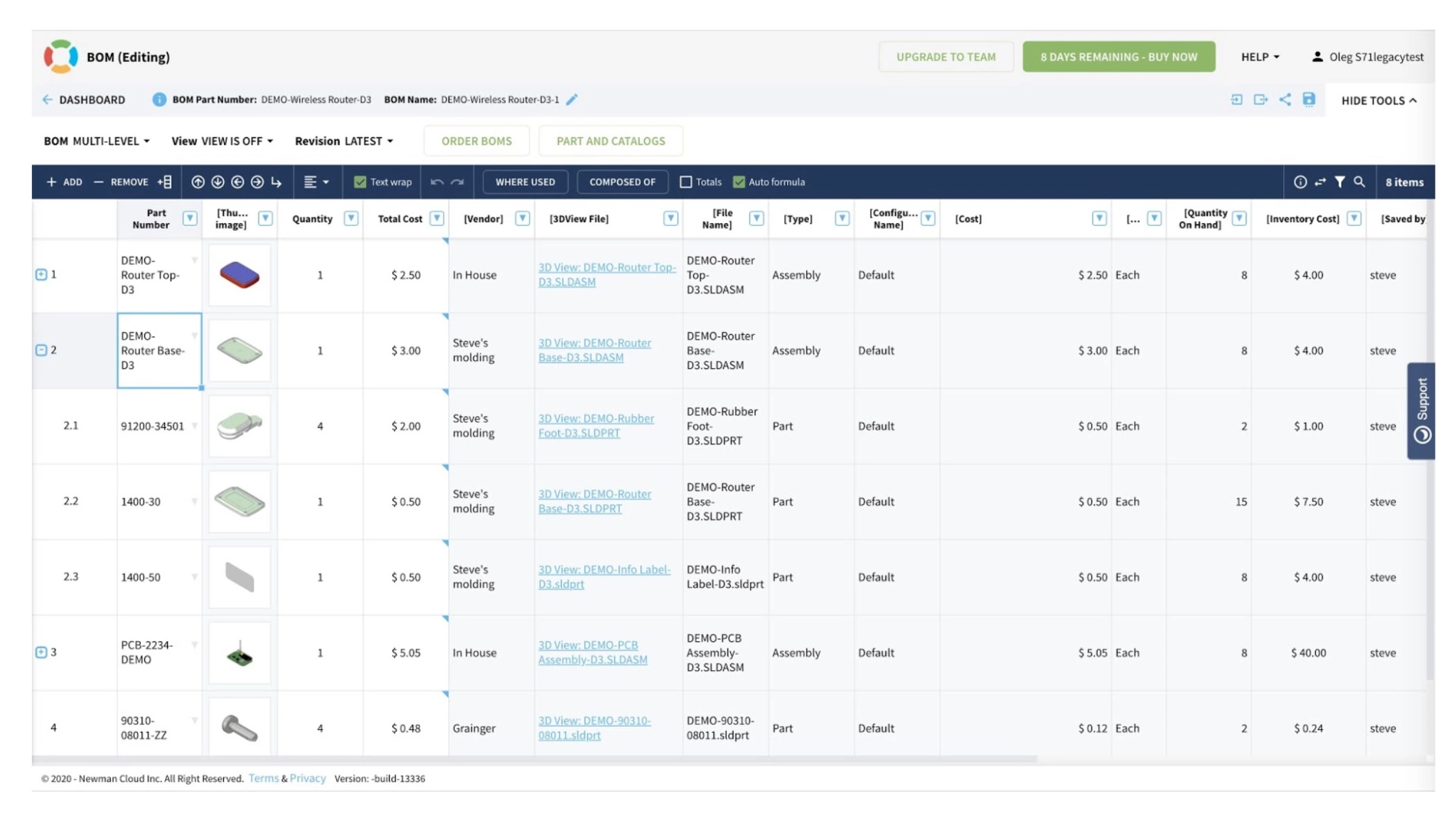

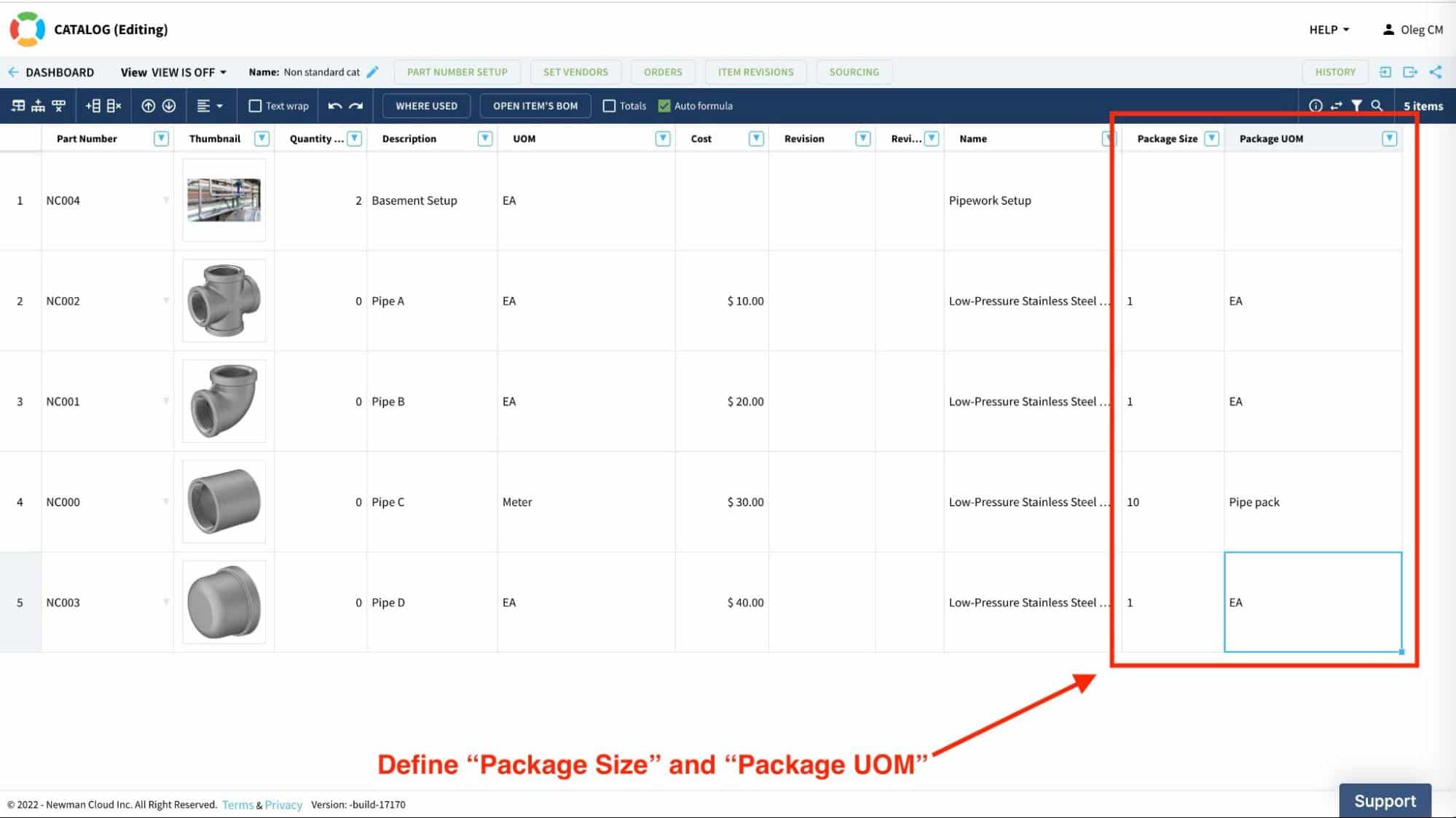

In today's digital age, managing a BOM manually is like trying to navigate with a paper map in a self-driving car. It's possible, but incredibly inefficient and prone to errors. Technology has revolutionized BOM management, making it easier than ever to create, maintain, and share BOM information across the organization. Embracing technology is crucial for unlocking the full potential of your BOM and streamlining your procurement processes.

Enterprise Resource Planning (ERP) systems often include BOM management modules, allowing you to centralize your BOM data and integrate it with other business functions, such as inventory management, production planning, and accounting. This integration provides a single source of truth for all product-related information, eliminating data silos and ensuring consistency across the organization. ERP systems are often essential in this day and age.

Product Lifecycle Management (PLM) systems are also powerful tools for managing BOMs, particularly in industries with complex products and long product lifecycles. PLM systems provide a comprehensive platform for managing all aspects of a product, from design and development to manufacturing and end-of-life. A great PLM makes managing BOMs for complex products easier than ever.

Cloud-based BOM management solutions are another option, offering flexibility, scalability, and accessibility. These solutions allow you to access your BOM data from anywhere, at any time, and collaborate with colleagues and suppliers in real-time. No matter which solutions you choose to use, technology is the single best way to ensure BOM accuracy and up-to-dateness. You can even find niche softwares that are tailored to your specific industry or purpose.

Finally, remember the integration is key! You will get the best performance out of your technology by integrating it into a holistic system. Data must flow freely from one piece of software to another to ensure that the correct version of the BOM is being referenced by everybody.

Optimizing Procurement with BOM

5. Tips for Effective BOM Implementation

Having a BOM is one thing, but using it effectively to optimize your procurement processes is another. To truly unlock the power of your BOM, it's essential to follow best practices for implementation, maintenance, and utilization. This means establishing clear processes, training your team, and continuously monitoring and improving your BOM management practices.

First and foremost, establish clear roles and responsibilities. Who is responsible for creating, maintaining, and updating the BOM? Who has the authority to approve changes? Clearly defining these roles ensures accountability and prevents confusion. This should be established at the beginning. In order to manage a BOM effectively, you must delegate specific duties to each person.

Secondly, implement a change management process. Any changes to the BOM should be properly documented and approved before being implemented. This prevents errors and ensures that everyone is working with the latest version of the BOM. Remember that integration is key, and a change that is made to one BOM might affect other BOMs. Ensure that changes are reflected correctly across the entire system.

Thirdly, regularly review and update your BOM. Products change, suppliers change, and manufacturing processes change. It's essential to keep your BOM up-to-date to reflect these changes and ensure its accuracy. An outdated BOM is as useful as a broken compass. Without a regular check and update, a BOM is essentially useless. Therefore, an audit of your BOM should happen at least quarterly.

Finally, make sure you have a process for auditing and verifying BOM information. Conduct regular audits to ensure that the BOM accurately reflects the actual materials used in production. This helps identify any errors or discrepancies and ensures that your procurement processes are based on accurate information. This is an essential piece of ensuring your data is accurate.